Automation vs. Information Technology: The

Smart Manufacturing Priority

Key Considerations for Industry 4.0 Implementation

The Modern Manufacturing Dilemma

In Industry 4.0 implementation, manufacturers face a critical question: Should industrial automation precede information technology (IT) infrastructure? This analysis examines both approaches through practical smart factory examples.

Industrial Automation

Core components:

- Precision sensors & transmitters

- PLC/DCS control systems

- Real-time data acquisition

Information Technology

Key systems:

- ERP/MES platforms

- Cloud-based analytics

- Digital workflow management

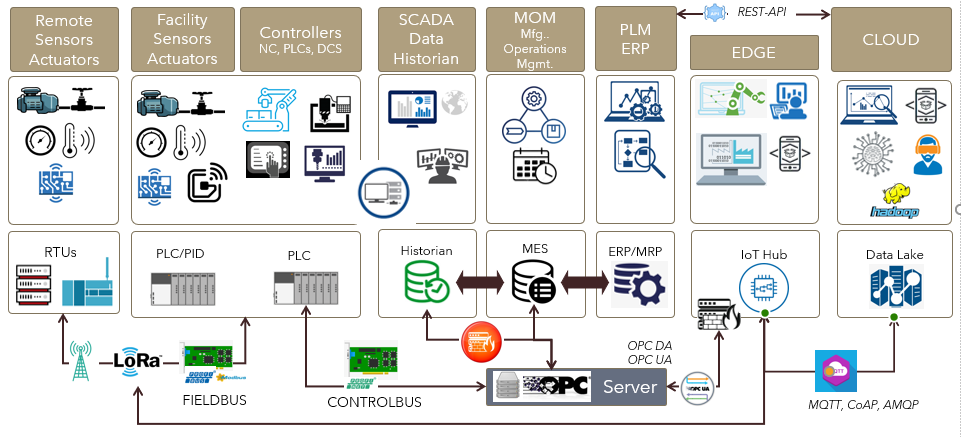

Three-Layer Manufacturing Framework

1. Field Level Operations

Sensors and actuators collecting real-time production data

2. Control Systems

PLCs and SCADA systems managing process execution

3. Enterprise Integration

ERP/MES utilizing data for business optimization

Practical Implementation: Beverage Production

Customization workflow:

- Barcode-driven formula adjustments

- Real-time valve control systems

- Automated production line switching

Implementation Strategy

“Reliable automation forms the essential foundation for effective digital transformation.”

Recommended implementation phases:

- Automation infrastructure deployment

- Data integration layer implementation

- Enterprise IT system integration

Start Your Smart Manufacturing Journey

Post time: Apr-10-2025