Introduction

The accuracy and reliability requirements for the measurement and control of sewage flow in oilfield sewage treatment stations are getting higher and higher. This article introduces the selection and operation and application of electromagnetic flowmeters. Describe its characteristics in selection and application.

Flow meters are one of the few instruments that are harder to use than to make. This is because the flow rate is a dynamic quantity, and there is not only viscous friction in the liquid in motion but also complex flow phenomena such as unstable vortices and secondary flows. The measuring instrument itself is affected by many factors, such as pipeline, caliber size, shape (circular, rectangular), boundary conditions, physical properties of the medium (temperature, pressure, density, viscosity, dirtiness, corrosiveness, etc.), fluid flow state (turbulence state, velocity distribution, etc.) and the influence of installation conditions and levels. Faced with more than a dozen types and hundreds of varieties of flow meters at home and abroad (such as volumetric, differential pressure, turbine, area, electromagnetic, ultrasonic, and thermal flow meters that have been developed successively), how to Reasonable selection of factors such as flow state, installation requirements, environmental conditions, and economy are the premise and basis for a good application of flow meters. In addition to ensuring the quality of the instrument itself, the provision of process data and whether the installation, use, and maintenance of the instrument are reasonable are also very important. This article introduces the selection and application of an electromagnetic flow meter.

Electromagnetic flow meter selection

With the development of science and technology, automatic detection technology has also been greatly developed, and automatic detection instruments have also been widely used in sewage treatment, so that sewage treatment plants not only save a lot of manpower and material resources but more importantly, they can be timely Make adjustments to the process. This article will take Hangzhou Asmik’s electromagnetic flow meter as an example to introduce the application of automatic detection instruments in sewage treatment and some existing problems.

Structural principle of electromagnetic flow meter

An automatic detection instrument is one of the key subsystems in the automatic control system. A general automatic detection instrument is mainly composed of three parts: ① sensor, which uses various signals to detect the measured analog quantity; ② transmitter, which converts the analog signal measured by the sensor into a 4-20mA current signal and sends it to the In the programmable logic controller (PLC); ③ display, which displays the measurement results intuitively and provides the results. These three parts are organically combined, and without any part, they cannot be called a complete instrument. The automatic detection instrument has been widely used in industrial production because of its characteristics of accurate measurement, clear display, and simple operation. Moreover, the automatic detection instrument has an interface with the microcomputer inside, and it is an important part of the automatic control system. It is called “The Eyes of an Automation Control System”.

Electromagnetic flow meter selection

In oilfield production, a large amount of oily sewage will be produced due to the needs of the production process, and the sewage treatment station must monitor the flow of sewage. In previous designs, many flow meters used vortex flow meters and orifice flow meters. However, in practical applications, it is found that the measured flow display value has a large deviation from the actual flow, and the deviation is greatly reduced by switching to an electromagnetic flow meter.

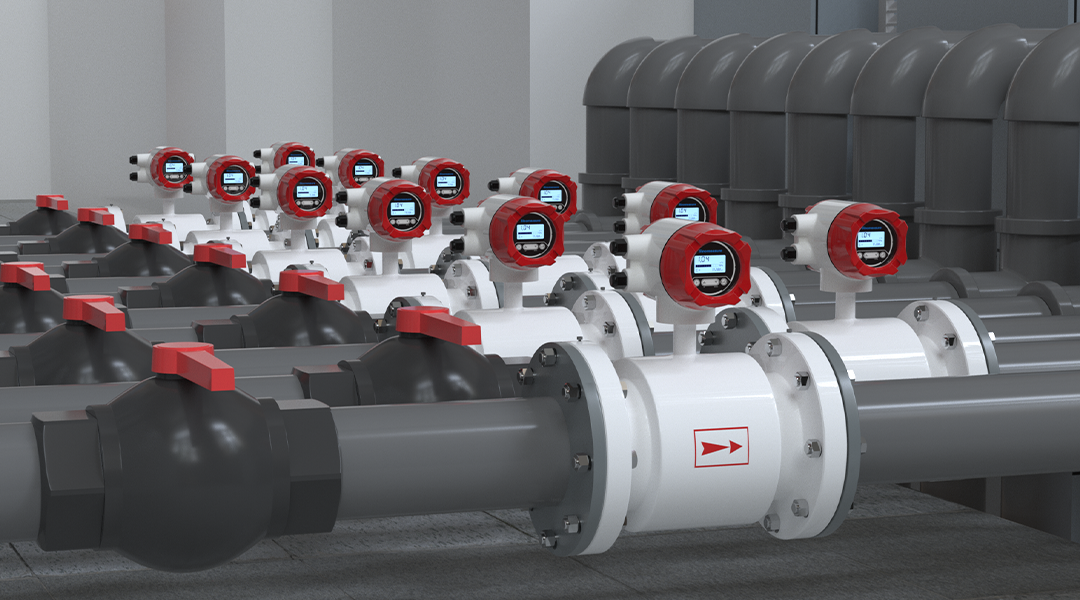

According to the characteristics of sewage with large flow changes, impurities, low corrosion, and certain electrical conductivity, electromagnetic flowmeters are a good choice for measuring the flow of sewage. It has a compact structure, small size, and convenient installation, operation, and maintenance. For example, the measuring system adopts an intelligent design, and the overall sealing is strengthened, so it can work normally in harsh environments.

The following is a brief introduction to the selection principles, installation conditions, and precautions of electromagnetic flowmeters.

Selection of Caliber and Range

The caliber of the transmitter is usually the same as that of the piping system. If the piping system is to be designed, the caliber can be selected according to the flow range and flow rate. For electromagnetic flow meters, the flow rate is 2-4m/s is more suitable. In special cases, if there are solid particles in the liquid, considering the wear and tear, the common flow rate ≤ 3m/s can be selected. For the easy-to-attach management fluid. The flow velocity ≥ 2m/s can be selected. After the flow velocity is determined, the transmitter caliber can be determined according to qv=D2.

The range of the transmitter can be selected according to two principles: one is that the full scale of the instrument is greater than the expected maximum flow value; the other is that the normal flow is greater than 50% of the full scale of the instrument to ensure a certain measurement accuracy.

Selection of temperature and pressure

The fluid pressure and temperature that the electromagnetic flow meter can measure are limited. When selecting, the operating pressure must be lower than the specified working pressure of the flow meter. At present, the working pressure specifications of domestically produced electromagnetic flowmeters are: the diameter is less than 50mm, and the working pressure is 1.6 MPa.

Application in the sewage treatment station

The sewage treatment station generally uses the HQ975 electromagnetic flow meter produced by Shanghai Huaqiang. Through investigation and analysis of the application situation of the Beiliu sewage treatment station of the No. A total of 7 flow meters including backwashing, recycling water, and external flow meters have inaccurate readings and damage, and other stations also have similar problems.

Current status and existing problems

After several months of operation, due to the large size of the incoming water flow meter, the measurement of the incoming water flow meter was inaccurate. The first maintenance did not solve the problem, so the water flow can only be estimated by external water delivery. After one year of operation, other flow meters suffered from lightning strikes and repairs, and the readings were inaccurate one after another. As a result, the readings of all electromagnetic flow meters have no reference value. Sometimes there is even a reverse phenomenon or no words. All water production data are estimated values. The production water volume of the whole station is basically in a state of no measurement. The water volume system in various data reports is an estimated value, lacking accurate actual water volume and treatment. The accuracy and authenticity of various data cannot be guaranteed, which increases the difficulty of production management.

In daily production, after the instrument has a problem, the station and mine metering personnel reported it to the competent department many times and contacted the manufacturer for repairs many times, but there was no effect, and the after-sales service was poor. It was necessary to contact the maintenance personnel many times before arriving at the scene. The results are not ideal.

Due to the poor accuracy and high failure rate of the original instrument, it is difficult to meet the requirements of various measurement indicators after maintenance and calibration. After many investigations and studies, the user unit submits an application for scrapping, and the competent department of measurement and automatic control of the unit is responsible for approval. . The HQ975 electromagnetic flow meters that have not reached the specified service life, but have a long service life, serious damage or aging deterioration are scrapped and updated, and other types of electromagnetic flowmeters are replaced according to the above selection principles in accordance with the actual production.

Therefore, reasonable selection and correct use of electromagnetic flowmeters are very important to ensure measurement accuracy and prolong the service life of the instrument. Flow meter selection should be based on production requirements, starting from the actual situation of instrument product supply, comprehensively considering the safety, accuracy and economy of measurement, and determining the method of flow sampling device and the type of measuring instrument according to the nature and flow of the measured fluid and specifications.

Correctly selecting the specifications of the instrument is also an important part of ensuring the service life and accuracy of the instrument. Special attention should be paid to the selection of static pressure and temperature resistance. The static pressure of the instrument is the degree of pressure resistance, which should be slightly greater than the working pressure of the measured medium, generally 1.25 times, to ensure that no leakage or accident occurs. The selection of the measuring range is mainly the selection of the upper limit of the instrument scale. If it is selected too small, it will be easily overloaded and damage the instrument; if it is selected too large, it will hinder the accuracy of measurement. Generally, it is selected as 1.2 to 1.3 times of the maximum flow value in actual operation.

Summary

Among all kinds of sewage flow meters, the electromagnetic flow meter has better performance, and the throttling flow meter has a wide range of applications. Only by understanding the respective performances of the flow meters can the flow meter be selected and designed to make the measurement and control of sewage flow Accuracy and reliability requirements are met. On the basis of ensuring the safe operation of the instrument, strive to improve the accuracy and energy saving of the instrument. For this reason, it is necessary not only to choose a display instrument that meets the accuracy requirements but also to choose a reasonable measurement method according to the characteristics of the measured medium.

In short, there is no measurement method or flow meter that can adapt to various fluids and flow conditions. Different measurement methods and structures require different measurement operations, usage methods, and usage conditions. Each type has its unique advantages and shortcoming. Therefore, the best type that is safe, reliable, economical, and durable should be selected on the basis of a comprehensive comparison of various measurement methods and instrument characteristics.

Post time: Feb-10-2023