SUP-LDG Sanitary electromagnetic flowmeter for food processing

-

Specification

| Product | Sanitary type electromagnetic flowmeter |

| Model | SUP-LDGS |

| Diameter nominal | DN15~DN1000 |

| Nominal pressure | 0.6~4.0MPa |

| Accuracy | ±0.5%,±2mm/s(flowrate<1m/s) |

| Repetitiveness | 0.2% |

| Liner material | PFA, F46, Neoprene, PTFE, FEP |

| Electrode material | Stainless steel SUS316, Hastelloy C, Titanium, |

| Tantalum, Platinum-iridium | |

| Medium temperature | Integral type: -10℃~80℃ |

| Split type: -25℃~180℃ | |

| Ambient temperature | -10℃~55℃ |

| Power supply | 100-240VAC,50/60Hz / 22VDC—26VDC |

| Electrical conductivity | Water 20μS/cm other medium 5μS/cm |

| Ingress protection | IP65, IP68(optional) |

| Product standard | JB/T 9248-2015 |

-

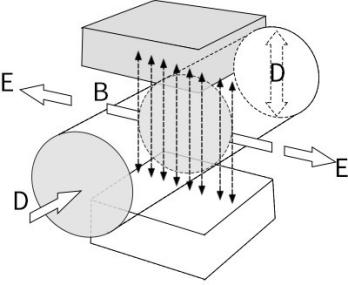

Measuring principle

The working principle of the electromagnetic flowmeter is based on Faraday’s law, which measures conductive media with a conductivity greater than 5μs/cm and a flow range of 0.2 to 15 m/s. An electromagnetic flow meter is a volume flow meter used to measure the flow rate of liquid through a pipeline.

The measurement principle of a magnetic flowmeter can be described as: when a liquid passes through a pipe with a diameter of D at a flow rate of v, the magnetic flux density generated by the excitation coil is B, and the following electromotive force E is proportional to the flow rate v:

| Where: E-Induced electromotive force K-Meter constant B-Magnetic induction density V-Average flow speed in cross-section of measuring tube D-Inner diameter of measuring tube |

|

-

Introduction

SUP-LDGS sanitary electromagnetic flowmeter is applicable for all food grade conductive liquids measure, such as drinking water, food processing, pharmaceutical industry and many others. Typical applications are monitoring accurate measurements in liquid, metering and custody transfer.

Noted: the product strictly prohibited to be used in explosion-proof occasions.

-

Application

Electromagnetic flowmeters have been used throughout industries for more than 60 years. These meters are applicable for all conductive liquids, such as: Domestic water, industrial water, raw water, ground water, urban sewage, industrial wastewater, the processed neutral pulp, pulp slurry, etc

-

Automatic calibration line